UAS Challenge

Hi there! We are Aerobotic Tech Team Twente (A3T), one of the student teams of the university. Our team deals with multiple drone-related challenges, in total we participate in four different challenges. In this article, we will focus on the IMechE UAS Challenge 2019.

This yearly challenge consists of a simulated humanitarian rescue mission. An example of such a rescue mission is delivering first aid, water and food to survivors in an area hit by earthquakes. Teams of Undergraduate and taught Postgraduate students from international universities compete in the designing, constructing, developing and demonstrating an Autonomous UAS (Unmanned Aircraft System). The system is required to operate autonomously, performing a series of tasks such as area search, navigating waypoints, accurately dropping Aid Packages and returning to base via a defined route. The key challenges involved are autonomy, optimising the configuration and structure of the UAV for the mission, and designing an accurate payload delivery system.

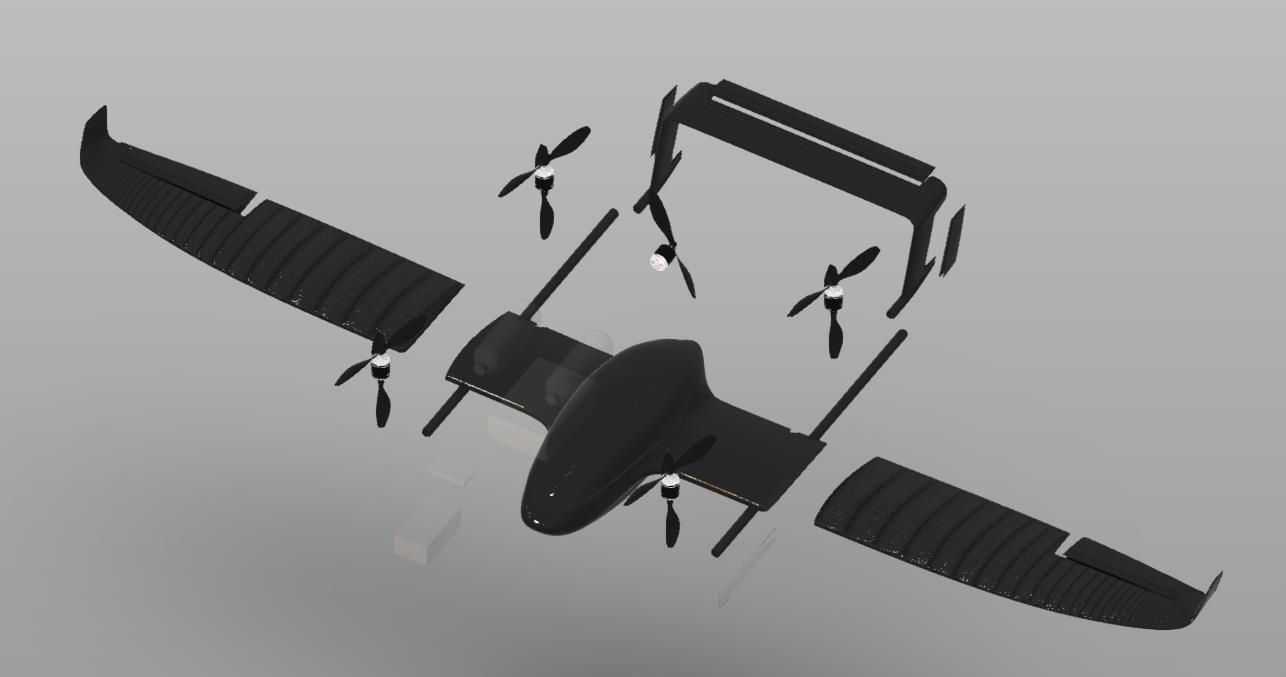

After performing trade studies, we settled on a Vertical Take-Off and Landing (VTOL) - Plane configuration that required a lot of optimising in energy and power consumption. We simulated the power consumption over time for different specifications of components and settled on an octa-plane configuration, which means 8 motors are used for VTOL and one for a forward motion. Since these VTOL motors were required for only ~5% of the mission flight time, we traded the power-energy costs for weight reduction. The total power consumption of the UAV in VTOL was about 2.5 kW as compared to about 500 W in plane mode. The VTOL motors weighed only 50g each with the propeller, putting the total VTOL weight cost at 400g. Since we were 5 times more efficient in plane mode, we had enough battery capacity to complete the required mission flight times.

Because the optimising of the structure was so important, another big challenge was the building of a high-quality frame. A lot of different materials can be used for the frame of a UAS. We wanted to use the lightest and strongest material available, carbon fibre. Unfortunately, although carbon fibre is a great material, it is quite expensive. The standard way to make a carbon fibre frame is to use a mold. However, the making of a mold is even more expensive and impractical, since the frame would only be built once and then the expensive mold could be thrown away. Fortunately, we found a company called Fiberneering that became our partner and provided us with their in-house developed FRP3D (3D printed composites). This method is able to combine a 3D printed substructure and the carbon fibre into one. This technique gave us the ability to build the frame of the drone in a cheap and efficient way. The freedom of the 3D-printing gave us all the possibilities in designing the frame, as you can see in the images.

We were unfortunately not able to fly our drone at the UAS Challenge, because of a crash two weeks prior to the event. Nevertheless, the team gained tremendous knowledge and experience from this challenge, which will be included in the new version of the drone that is already being developed by the new team. But like we said, it’s not the only project we are working on. Check our website and social media to discover all the projects being made reality this year.