NTS’ knowhow of propulsion and print systems considerably shortens customers’ time-to-market

System architect Mike Curvers (47) develops propulsion and printing systems at NTS. Twenty years ago, he started at a predecessor of NTS. He saw his professional field change: mechanical machines became mechatronic, motion control continued to become more important and the demand for printing flexible, customised series continued to grow. Moreover, technologies like printing reliefs and Additive Manufacturing entered the market. The know-how NTS has in the field of propulsion and system printers is unique in the market. “Our knowledge and experience in the field of motion control, electronics and mechatronics cannot be found at any other company. That helps our customers to considerably shorten their time-to-market.”

Mike was already interested in technology at a very early age. During his study he found electronics especially appealing. In practice he discovered that he was mainly fascinated by engines and propulsion. That is why Mike chose to start at Te Strake, one of NTS’ predecessors.

“That was twenty years ago,” Mike says: “and now I still work here. In that time a lot has changed, the company has professionalised a great deal. Although we were already a forerunner back then when it came to our machines for textile printing for instance. That was a very innovative product.”

Understanding exactly what happens

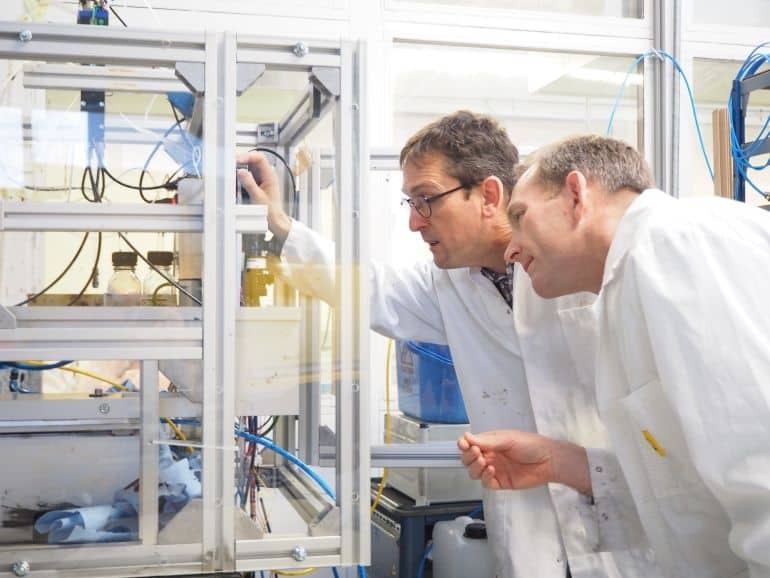

“Back then those machines were entirely mechanical. At a later moment in time they became mechatronic: a combination between electronics, software and mechanics. The textile printer is an example of an extensive project that I have worked on. It is a system printer, motion control in this case is very complex, the ink needs to end up in the exact right position. I want to be able to understand what happens exactly and I want to see that it works.”

From customer question to project plan and concept

“Recently we received a question from a customer that wanted to develop a bar in which printheads needed to be integrated. At such a moment we demonstrate the customer what we have already done before and what our competences are. The customer was enthusiastic, we showed him what he wanted to see and he chose to work with NTS. After he had sent us his requirements, we made a project proposal and then you translate it in a project plan and a concept.”

“We are now working on the next step. We are going to further investigate the things we have and the aspects that are difficult to develop or produce. In this process we look at whether it is possible to manufacture it and whether it is possible to clean all components. We map the feasibility. The customer does not have the knowhow to do that himself.”

Robots Kulicke & Soffa are still being built

“Another example of a system that I have worked on in the past and that is still in production, is a robot that we developed for Kulicke & Soffa. These robots are used for assembling circuit boards. I started developing these robots 17 or 18 years ago and they are still being used. The robots of course are continuously being updated by NTS’ Assembly division. When a certain component is not available for instance an alternative is looked for. The fact that the robots are still being used, is really nice.”

“Sometimes we also develop machines that eventually do not obtain the results that the customer expected. Take the inkjet printer for textile as an example. Seen from a technical perspective the machine worked perfectly, but from a commercial perspective the inkjet printhead was simply too expensive. That is something you see more often in the inkjet print market: some projects are really innovative which does not always make it easy to predict the commercial viability.”

Best project ever: printer of 800 kilos with high precision printheads

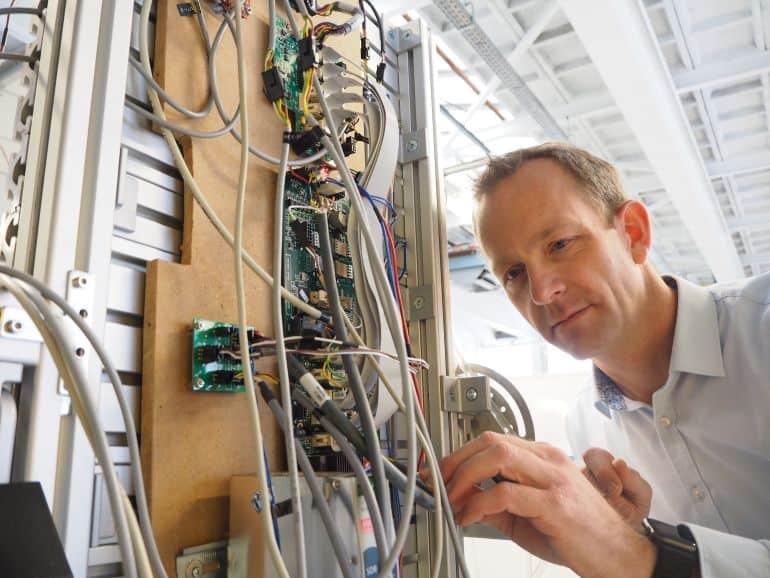

“The best project I have ever worked on is a very large printer for Agfa. It is a large industrial printer with a print system that weighs 800 kilos and has 64 printheads that need to move with an accuracy of 10 micrometre. We were mainly responsible for the motion control and electronics. That was really, very nice. It was even patented.”

“Agfa has a sound knowledge of inkjet, but does not have enough expertise of this type of motion control. We have developed the printer together with three parties. A lot of the testing took place in Germany. That was a very nice period, the collaboration was very good. During daytime we worked hard and, in the evenings, we went out to dinner and explored the environment. It was challenging, educational and fun.”

“In the end about 30 of this type of machines have been manufactured and I am very proud of it. The machines among others are used to print commercial posters. The well-known glass display posters that you for instance can see in subway stations in Great-Britain. Eventually the image quality of the inkjet printer was better than an offset image. For that time, it was really unique.”

Inkjet offers great flexibility

“The advantage of inkjet over offset is that it offers you great flexibility. It is extremely suited for printing small series or limited editions. You can also apply special effects, like printing layers, fast marketing campaigns where you print relief on packaging, printing a wooden pattern on boards, printing panels and so on. It offers you a wide range of possibilities.”

Ever smaller series

“The wish to be able to be flexible and print small customised series is something you hear a lot in the market. You don’t see a lot of large series anymore. Certainly not in Dutch industry. It is all about small series and large flexibility. Products generally have a continuously shorter lifespan. Think of potato chips, in the past you could choose between a natural or sweet pepper flavour, now you continuously have new flavours. These new products repeatedly require new packaging.”

3D printing is on the rise

“Another trend you see in the market is 3D printing. Initially it was mainly used for prototyping purposes but now more and more often it is used for printing the final product. It also concerns products that cannot be produced in one piece by using another production technique, a chess piece for example. Additive Manufacturing is rapidly developing. A continuously greater variety of materials are being printed.”

Printing on products

“Inkjet printing is also evolving. One of the new developments in the field of inkjet is printing directly on the final product. Think of plastic bottles. We print directly on the bottle and because of this you do not need to use a plastic wrap. By doing so, you reduce the required number of activities and the logistics, which reduces your footprint and makes it better for the environment. Furthermore, personalising products is something you see more and more often.”

Knowledge NTS has of propulsion and print systems is unique in Europe

“What NTS does in the field of propulsion and print systems and the experience we have in this field is unique in Europe. Not a single other company has the expertise that we have in the combination of motion control, electronics, software and mechatronics. We do not sell products of our own. Our services consist of helping our customers design and develop customised print systems and parts of these systems in order to manufacture them in series.”

Not a single other company knows all parts and can also manufacture them

“There are a lot of other companies with a specialism in specific parts but there isn’t a single other company that has knowledge of all parts and that can also manufacture those parts. When NTS would not have had these competencies, a considerable number of the print systems that are currently on the market, simply would not have existed.”

Expertise NTS shortens time-to-market

“Moreover, our expertise helps customers to develop and manufacture the machine they have in mind in a much shorter period of time. They could do it themselves and hire people for it but the enormous advantage NTS offers, is that we don’t have to go through the learning curve. We already have the experience we need in the field of inkjet and in the field of manufacturing and assembly.”