Afterlife: Tobias Feijten

Let’s start of a little philosophical: where does time go when it passes? Of course it goes in the past, but it seems that it doesn’t always get in our memories in a linear fashion. It seems like a couple of weeks ago when I was working on my graduation assignment, attending almost all of Scintilla’s activities and doing many helpful things at Scintilla. However, I’ve been working already over one and a half year (and scarcely present at Scintilla gatherings), and as such, many things happened.

Study period (2011 – 2017)

Like many of you, I have walked the corridors and stairs in the Carré and Zilverling buildings during my studies. For me, the start was about 8 years ago, when there still was no TEM but we were just bothered with finishing courses and projects. I started off still living with my parents in a small town near Hengelo, so I could first check out the study load and see how that would play out. About half a year later, I realized I wanted to be more independent so I moved to a dormitory at the campus. At the same time, I joined a committee at Scintilla (the parents day committee) since I wanted to experience more than just the study and grow my network at the same time.

During my studies I have done a couple of committees at Scintilla and outside, such as the STORES, the iDB (in which I’m still active and which develops the web site, including registration, scenarios, logistics and much more, for the Kick-In of the University of Twente), the Borrel and the safety response officers (BHV). I even founded my own company together with a fellow active Scintilla member (BobV), in which we do soft- and hardware development: Drenso. Each time I joined another committee I wanted to see whether my grades and study progress would deteriorate. After two and a half years, that still was not the case so I decided to set up and become part of the 85th board of Scintilla.

85th board of E.T.S.V. Scintilla

Together with 4 (5 if you count our administrator) great guys we led the study association from September 2014 to September 2015. During this time, we set up a symposium, prepared the 10th lustrum, kicked off a study tour to the United States and Canada (in which I participated as well), updated the articles of association (statuten in Dutch) and wrote the long term policy for 2015-2019. In my function of treasurer I came along some policy shortcomings, for which I drafted some addendums to the by-laws of Scintilla, of which most are still being used. Besides the serious work, we also had a lot of fun organising activities, going to constitution drinks and enjoying bonding activities when another association ‘braste’ something from Scintilla.

I already started my master’s degree on biochemical sensors during my board year, which means I had a head start of 10 ECTS when my board year was finished. As such, I was able to enjoy the study tour ‘Beyond Frontiers’ with a holiday afterwards, and still finish the necessary courses in the first year of the master’s programme. For my internship I was intent on doing it in a foreign environment within a company. With the help of Jan Eijkel of BIOS I was able to find a nice company in China which was willing to accommodate my internship. If you want to know more about this internship you can read it in Vonk 35-2. After that I did my master’s assignment at the BIOS group and even went to Switzerland with them for a week to find out what research they were doing there. My graduation was at the 31st of August in 2017, and that finalized my studies. Now what?

Graduating

YER/Benchmark Electronics (2017 – now)

So you’re graduated and thrown in the ‘big bad world’. Recruiters will fly towards you like vultures (already during your final phase of the study programme). This happened to me as well, so I could take my pick of many interesting career options. However, I had no idea what I wanted to spend the rest of my life on (all right, this is a little dramatic, but it can have a large impact…). When somebody from YER (a recruiting and secondment company) approached me to tell me they had a nice career opportunity for me, I went to them to discuss the details. Of course, I wanted to keep doing work for my own company, so it was important for me that the job and my company can be combined. They offered me a programme in which I could develop my soft skills and my business skills by 6-weekly training sessions and intensive coaching, while working at one of their clients. If I decided that the client I was working wasn’t the right match, it would be possible to change to another client without losing my employment. That sounded very interesting to me, so after some deliberation I took them up on their offer.

After signing the contract they busied themselves with finding clients which would match my interests. They managed to find a job at Benchmark Electronics in Almelo which sounded very good in my opinion. Of course you should all at least have heard the name Benchmark Electronics, since they have collaborated with Scintilla for some time now, being present at the symposium ‘City of the Future’ and giving lunch lectures once in a while. For those not acquainted with Benchmark, here is a short recap. Benchmark Electronics Almelo has about 500 employees, 150 of which are working in product development. Besides development it also is a manufacturing site. Most of the projects they work on are for clients in the industrial, medical and avionics business, such as Airbus, ASML, Fluke and many more. Projects vary from consulting to complete design and industrialization of products based on back of the envelope (‘bierviltje’) ideas. (a little propaganda can go a long way…)

I was to be employed as a hardware design engineer, which means that I do the design and verification of the electrical part of development projects within Benchmark. In order to do so I have to know what a product should do exactly, what technologies can solve certain problems, whether they are available on the market in a way we can implement them and then make a schematic in order to implement this functionality. I have to take all factors of the design process and the wishes of the customer into account when doing my job, such as quality, price, manufacturability, testability, safety and so on. In order to do that a lot of communication is part of my job. I have to talk to the project team, fellow hardware design engineers, supply chain management, customers, manufacturing engineers and sometimes even the management team of product development.

In the beginning, I was not sure whether the job at Benchmark would be my dream job. I was set on trying it for a year, then evaluating whether it satisfied my wishes for a job and if not, transfer to a different company (thereby leveraging the offer YER made me). However, after a year I realized the job is perfect for me right now. There are many aspects about my job I like, and I will treat them here. The biggest pro of the job at Benchmark is the atmosphere at the company. The atmosphere is quite informal, it is very easy to get to know colleagues and have a little fun with them. Next to that, if I want to know something (hey, we don’t know everything after graduation) I can just walk to a colleague and they will help me right away, whether it is a question which can be answered in a couple of seconds or a mini-lecture of half an hour. It doesn’t matter whether the person is smothered in work or has some time on their hands, which is something unique in my opinion.

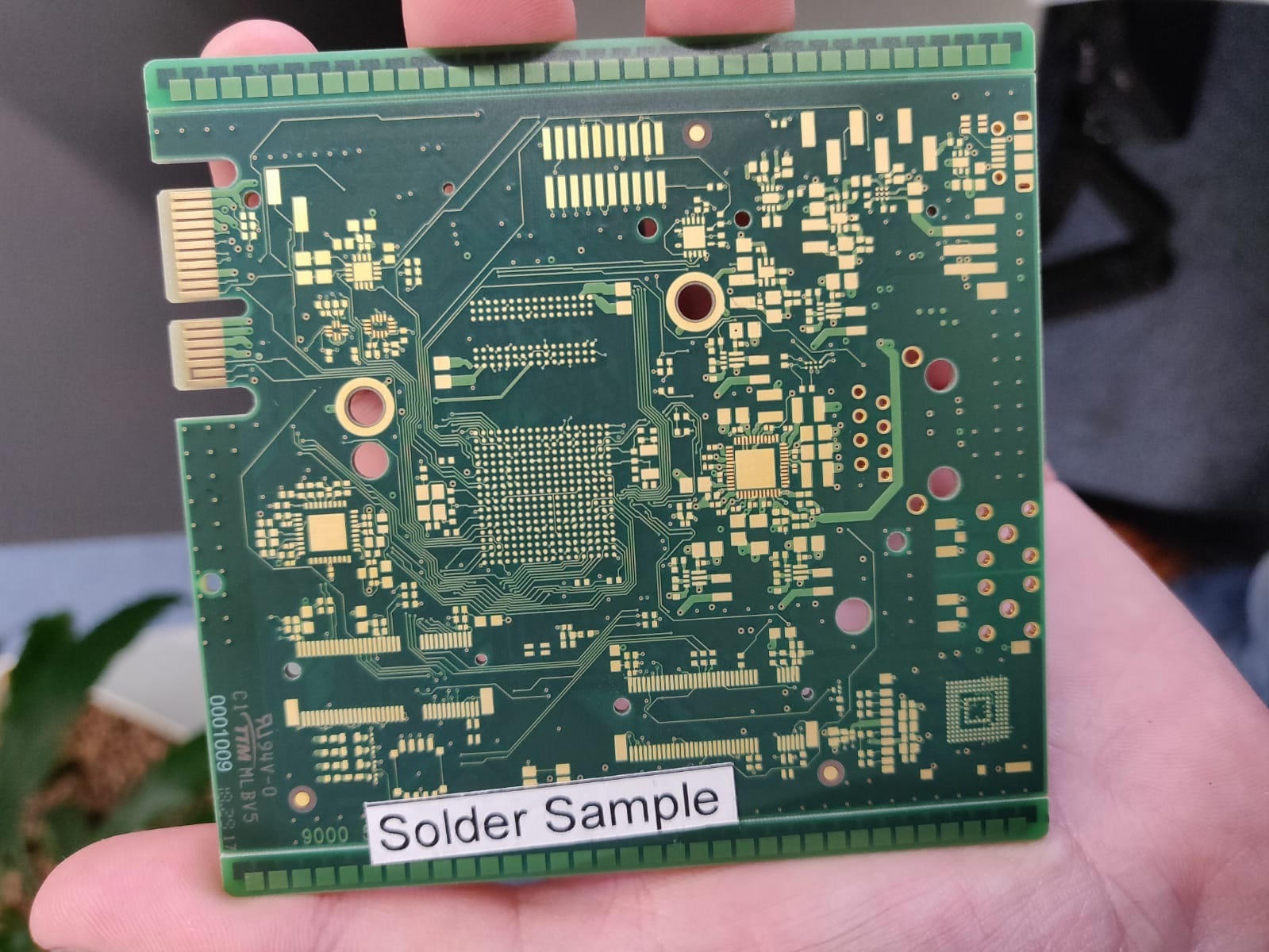

Solder Sample

Variation is another thing I really like about this job. It could be that one day I’m going to a customer to talk about a great new project they want us to do, the next day I’m going to a training or seminar about interesting technological subjects, the next day I review a design of a fellow design engineer and the next day I’m performing electronic measurements on my own design. Of course there are some less attractive tasks in the job as well, like documenting every choice and detail of a design, but that’s part of the job. I can tell you that it is very rewarding when you receive gratification for the good documentation you made from people in management, which is important to me as well. What really struck me as extraordinary is that you will get a lot of responsibility and freedom, even though you have just graduated and have no experience at all.

For the past one and a half year I have worked on my own solo project, which is a Benchmark internally driven development. The product is an embedded platform outfitted with a CPU, some working memory and Ethernet, and many slots for extension modules. These extension modules can provide functionality such as Wi-Fi, LTE (4G), LoRaWAN, NB-IoT, USB, CAN and much more. It can therefore be seen as a ‘professional’ Raspberry Pi, complete with a Linux software environment. I based the design on a project done by an intern some time before I started, which was somewhat similar but some of the requirements changed in the meanwhile. I first had to establish and finalize the requirements for the project, which I did by talking to the people involved in the project in the first place and researching what would be feasible to implement on the platform, given the constraints of the used CPU.

With a reviewed set of requirements I started on the design. As such, I started by drafting the schematics needed. In order to do so I could not just say ‘ah, here is a resistor of exactly this value, and a capacitor of exactly this value, and let’s use this ideal op amp’. I had to use real components with a certain tolerance, footprint, (vendor) availability and price. Within Benchmark, many components were already present in the internal component database including schematic symbol and PCB footprint. Using these components and some new components which haven’t been used before, I finalized the schematics and let more experienced people review them.

Of course, a schematic representation doesn’t give you a usable product. Therefore, I had to make a PCB layout using the more than 900 components I used. Since I had no experience with a complex board like this, I started in a very naïve way by making a small board outline and putting all the components on the board. Of course I asked my experienced colleagues about certain design techniques to make a successful layout in order to learn from previous mistakes. However, I did not take into account the space it would take to connect all the ICs and connectors on the board. After a couple of weeks I realized that I wasn’t going to manage to implement all of the functionality on the board dimensions I chose, which meant I had to restart the layout process. This was quite frustrating.

Some iterations and reviews later, the layout was ready to be ordered and manufactured and this part of the project was done. It was a fascinating feeling to hold my own design in my hands and finally see the real-life representation of the multi-coloured drawing I had been working on for some months. Of course, a thorough verification of the design was now imminent to find out whether all the requirements as set up are fulfilled by the product now produced. Some of the functionality was not implemented as should, which was valuable information to improve the product and make it into a good design. Currently I’m finalizing the verification of the second design iteration, which should finish my work for this project and allow me to transfer to the next exciting project.

During my time at Benchmark, although it being short, the management of the department noticed my accomplishments. During an ‘all employee meeting’, in which the financial results of the previous time and other important announcements are made for all of the 500 employees of Benchmark Electronics, I was appointed ‘employee of the year’ in 2018 for the design department! It was amazing (and a little awkward and embarrassing) to stand in front of 500 people, many of which I came to know, and have the vice president of development talk about my accomplishments and the way they saw me as a great example towards the rest of the department. Of course I see it as a great encouragement and think the team at Benchmark can achieve great things in the future.

Employee of the year

Not all my time is spent working at Benchmark, luckily. As mentioned I’m still doing work for my own company (which will create the next version of the sales program for the STORES!), enjoy playing the clarinet in an orchestra and doing fun stuff with friends and colleagues and I like travelling a lot. Next to that I’m still involved in helping Scintilla by checking the accounting each year as part of the Financial Audit Committee and advising the board as part of the Advisory council. It’s not that often I’m present at Scintilla activities anymore, but I try to at least stay connected by going to the General Meetings and activities for former board members. Twente is, after all, a great region!